The 3D printing materials market is poised for remarkable growth, driven by technological advancements, increasing adoption across industries, and rising demand for customized manufacturing solutions. As additive manufacturing continues to transform production processes, the choice of materials has become a critical factor influencing efficiency, durability, and application versatility. The future outlook of this market reflects a convergence of innovation, sustainability, and strategic investments aimed at capturing emerging opportunities.

Key Growth Drivers

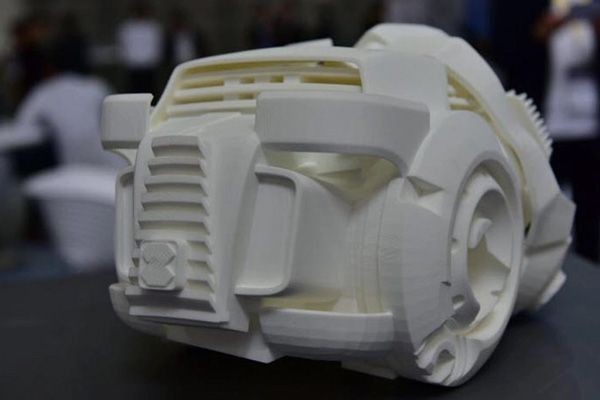

The expansion of the 3D printing materials market is fueled by several factors. Firstly, industries such as aerospace, automotive, healthcare, and construction are increasingly leveraging 3D printing to reduce production time, minimize waste, and enable complex geometries unattainable through traditional methods. High-performance polymers, metals, and composite materials are seeing heightened demand for functional and structural applications.

Additionally, the rise of customized consumer products, including dental implants, prosthetics, and fashion items, is accelerating the adoption of bio-compatible and flexible materials. This shift underscores the importance of materials that balance mechanical strength, biocompatibility, and cost-effectiveness. The growing focus on localized production and on-demand manufacturing further amplifies the need for versatile and easy-to-process materials.

Technological Innovations

Innovation is central to shaping the 3D printing materials market’s future. Advanced polymers with enhanced thermal and mechanical properties, metal alloys optimized for additive manufacturing, and composite materials with tailored characteristics are transforming the production landscape. Researchers are also exploring sustainable feedstocks, including recycled plastics and biodegradable polymers, aligning material development with global sustainability goals.

Nanomaterials and smart materials are expected to revolutionize applications in electronics, aerospace, and medical devices. Materials with embedded sensors or self-healing capabilities could redefine product lifecycles and maintenance protocols. Continuous innovation ensures that manufacturers can meet specific functional requirements while maintaining cost efficiency and performance reliability.

Regional Insights

Geographically, North America and Europe have historically led the 3D printing materials market due to established industrial bases, strong R&D infrastructure, and early adoption of additive manufacturing technologies. However, the Asia-Pacific region is emerging as a high-growth market, driven by industrial expansion, investments in manufacturing automation, and government support for technology adoption.

Emerging economies in the region are witnessing rapid industrialization, creating opportunities for localized production and material innovation. China, India, and Japan are investing heavily in both material research and the development of affordable, scalable 3D printing solutions. This regional diversification is likely to enhance global supply chains and improve access to advanced printing materials worldwide.

Challenges and Market Constraints

Despite the positive growth trajectory, the 3D printing materials market faces several challenges. High material costs, limited standardization, and technical limitations in printing complex alloys or composites can hinder adoption. Additionally, integrating new materials into existing industrial processes requires specialized equipment, skilled labor, and regulatory compliance, particularly in the medical and aerospace sectors.

Intellectual property concerns and material reproducibility issues also pose constraints. Manufacturers must invest in quality control and certification processes to ensure consistent performance. Overcoming these challenges is critical to sustaining long-term growth and expanding the application spectrum of 3D printing materials.

Strategic Opportunities

Opportunities in the 3D printing materials market are vast. Strategic collaborations between material manufacturers, 3D printer OEMs, and research institutions can accelerate innovation and reduce development timelines. The focus on eco-friendly and biodegradable materials presents a dual advantage—addressing environmental concerns while meeting consumer demand for sustainable products.

Moreover, the integration of AI and machine learning with additive manufacturing is expected to optimize material selection, printing parameters, and post-processing, further enhancing efficiency and reducing production costs. Companies that invest in research, regional expansion, and strategic partnerships are likely to gain a competitive edge in a rapidly evolving market.

Future Outlook

Looking ahead, the 3D printing materials market is expected to witness robust growth driven by technological innovation, cross-industry adoption, and sustainable practices. The market will increasingly favor materials offering superior performance, cost-efficiency, and environmental benefits. As the global manufacturing landscape evolves, additive manufacturing and material innovation will remain pivotal in shaping industrial strategies, enabling more efficient, customized, and sustainable production processes.

The future of the 3D printing materials market is not just about growth in volume but also about achieving higher functionality, sustainability, and adaptability, ensuring that industries worldwide can leverage the full potential of additive manufacturing technologies.