The Aerospace Foam Market is emerging as a critical segment within the global aerospace materials industry, driven by the continuous demand for lightweight, high-performance, and durable materials used in aircraft manufacturing and maintenance. Aerospace foams are widely utilized for thermal insulation, acoustic damping, vibration control, and structural reinforcement in both commercial and military aircraft. With the aviation industry focusing on fuel efficiency, passenger comfort, and safety compliance, aerospace foams are increasingly replacing traditional materials. This article presents a detailed and SEO-friendly analysis of the global aerospace foam market, based strictly on insights from Straits Research.

Market Size and Growth Outlook

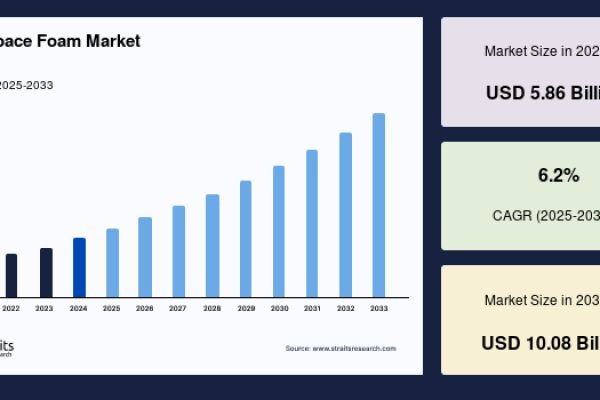

The global Aerospace Foam Market Size was valued at USD 5.86 billion in 2024 and is projected to reach from USD 6.23 billion in 2025 to USD 10.08 billion by 2033, growing at a CAGR of 6.2% during the forecast period (2025-2033).

The steady growth of the aerospace foam market reflects increasing aircraft production, rising demand for lightweight materials, and growing investments in next-generation aircraft and fleet modernization programs across major aviation markets.

Get Your Sample Report Here: https://straitsresearch.com/report/aerospace-foam-market/request-sample

Buy Report Now: https://straitsresearch.com/buy-now/aerospace-foam-market

Download Full Report: https://straitsresearch.com/report/aerospace-foam-market

Market Drivers

Rising Aircraft Production and Fleet Expansion

The expansion of global air travel and increasing demand for new commercial aircraft are major drivers of the aerospace foam market. Aircraft manufacturers are integrating advanced foam materials to reduce overall weight, improve fuel efficiency, and enhance cabin comfort. The growth of low-cost carriers and regional aviation is further supporting demand for aerospace foam across interiors and structural components.

Focus on Lightweight and Fuel-Efficient Materials

Fuel efficiency remains a top priority for airlines and aircraft manufacturers. Aerospace foams contribute to weight reduction without compromising structural integrity or safety. Their ability to provide insulation and vibration damping while remaining lightweight makes them essential in modern aircraft design.

Increasing Demand for Passenger Comfort and Noise Reduction

Aerospace foams are extensively used for acoustic insulation, seating, cabin panels, and flooring systems. Growing emphasis on passenger comfort, noise reduction, and in-flight experience is encouraging manufacturers to adopt high-performance foam materials in aircraft interiors.

Market Challenges

High Cost of Advanced Aerospace-Grade Foams

Aerospace foams must meet stringent safety, fire resistance, and durability standards, resulting in higher production and material costs. These elevated costs can impact adoption, particularly in cost-sensitive aircraft programs and aftermarket applications.

Stringent Regulatory and Certification Requirements

The aerospace industry is subject to strict regulations related to material performance, fire safety, and environmental compliance. Meeting certification standards can increase development timelines and costs, posing challenges for new entrants and smaller manufacturers.

Market Segmentation Analysis

By Foam Type

Polyurethane foam dominates the aerospace foam market due to its versatility, lightweight nature, and excellent cushioning and insulation properties. Polyethylene foam is widely used for thermal insulation and vibration control, while metal and ceramic foams are used in specialized applications requiring high-temperature resistance and structural strength.

By Application

Interior applications account for a major share of the market, including seating, cabin walls, overhead bins, and flooring systems. Insulation applications follow closely, driven by demand for thermal and acoustic control. Structural applications, though smaller in share, are gaining importance in advanced aircraft designs and military aviation.

By Aircraft Type

Commercial aircraft represent the largest segment due to high production volumes and ongoing fleet expansion. Military aircraft also contribute significantly, driven by defense modernization programs and demand for high-performance materials. General aviation and business jets account for a smaller but steady share of market demand.

By End User

Original equipment manufacturers dominate the market as aerospace foams are integrated during aircraft manufacturing. The aftermarket segment is growing steadily due to rising maintenance, repair, and overhaul activities and the need for replacement of interior components.

By Region

North America holds a leading share of the aerospace foam market due to strong aircraft manufacturing presence and defense spending. Europe follows closely, supported by major aircraft OEMs and technological advancements. Asia-Pacific is witnessing rapid growth driven by increasing air passenger traffic, expanding airline fleets, and rising aerospace manufacturing capabilities.

Top Players Analysis

-

BASF

BASF is a major supplier of high-performance polyurethane and specialty foams used in aerospace applications. The company focuses on lightweight materials that meet stringent safety and performance standards. -

Evonik Industries

Evonik Industries provides advanced polymer and foam solutions for aerospace interiors and insulation applications. Its strong emphasis on innovation supports adoption in next-generation aircraft. -

Zotefoams

Zotefoams specializes in high-performance polyethylene foams used for lightweight insulation and vibration control in aerospace applications. -

Rogers Corporation

Rogers Corporation supplies specialty foams and engineered materials designed for thermal management and acoustic insulation in aerospace environments. -

Solvay

Solvay offers advanced aerospace-grade materials, including foams and composites, used in structural and interior aircraft components.

Frequently Asked Questions (FAQs)

What are aerospace foams used for?

Aerospace foams are used for thermal insulation, acoustic damping, seating, vibration control, and lightweight structural applications in aircraft.

What is driving the aerospace foam market?

Key drivers include rising aircraft production, demand for lightweight and fuel-efficient materials, and increasing focus on passenger comfort.

Which aircraft segment dominates the market?

Commercial aircraft dominate due to large-scale production and continuous fleet expansion by airlines.

How fast is the aerospace foam market growing?

The market is expected to grow at a CAGR of 6.2% during the forecast period from 2025 to 2033.

About Us

Straits Research is a market intelligence company providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision-makers. Straits Research Pvt. Ltd. provides actionable market research data, especially designed and presented for decision making and ROI.