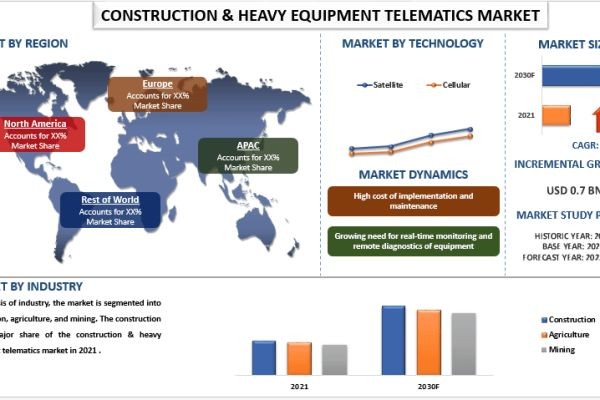

According to UnivDatos, the global construction and heavy equipment telematics market was valued at USD 0.7 billion in 2021 and is projected to grow at a CAGR of 16.0% through 2030.

Telematics technology has undergone significant advancements in recent years, becoming a cornerstone for efficiency and productivity in the construction and heavy equipment sector. As the industry moves toward smarter, more connected operations, telematics has emerged as a powerful tool for equipment monitoring, fleet management, and predictive maintenance.

The Evolution of Telematics in Construction

At its core, telematics combines telecommunications and informatics to transmit data over long distances. In construction, it’s used to collect, transmit, and analyze data from heavy machinery — helping companies make informed, real-time decisions about their operations.

One of the earliest and most transformative developments in this space is GPS tracking. While GPS has long been used to track vehicle locations, today’s telematics systems go much further. With real-time GPS integration, companies can monitor equipment movement, usage, and performance across multiple sites. This level of visibility helps reduce idle time, improve equipment allocation, and ultimately boost productivity.

The Power of IoT in Telematics

The integration of Internet of Things (IoT) technology has pushed telematics to new heights. IoT-enabled sensors collect vast amounts of data on everything from fuel consumption and engine health to operating hours and environmental conditions. This constant stream of information allows site managers to better understand equipment performance and usage trends, paving the way for smarter maintenance strategies and reduced downtime.

For example, if a sensor detects abnormal engine temperature or low oil pressure, the system can immediately alert operators — potentially preventing a costly breakdown.

Cloud Computing and Data Accessibility

With the amount of data generated by telematics systems, cloud computing plays a vital role in managing, storing, and analyzing this information. Cloud-based platforms give construction companies instant access to equipment data from any location, enabling centralized decision-making and cross-site coordination.

These platforms offer scalability and flexibility, meaning businesses can expand or refine their telematics infrastructure as their operations grow. Plus, with powerful dashboards and reporting tools, stakeholders can turn raw data into actionable insights without needing a deep technical background.

Advanced Analytics: Machine Learning and AI

As telematics systems continue to evolve, machine learning and artificial intelligence (AI) are adding another layer of intelligence to equipment management. These tools can process massive data sets to detect patterns and predict potential equipment failures before they happen.

By identifying subtle trends in machine usage or performance anomalies, AI-powered analytics can recommend optimal maintenance schedules, reducing unexpected downtime and extending the life of equipment. This not only saves money but also keeps projects on track.

Remote Monitoring and Safety Compliance

One of the most practical benefits of modern telematics is the ability to remotely monitor and manage equipment. Operators and site managers can receive real-time notifications for issues such as unauthorized use, excessive idling, or geofence breaches. This enhances both equipment security and operator accountability.

Additionally, remote monitoring supports regulatory compliance. By tracking emissions, usage hours, and safety parameters, telematics can help companies meet environmental and occupational health standards, reducing the risk of fines or shutdowns.

Access sample report (including graphs, charts, and figures): https://univdatos.com/reports/construction-and-heavy-equipment-telematics-market?popup=report-enquiry

The Need for Strong Cybersecurity

As with any connected technology, the growing reliance on telematics brings cybersecurity concerns. Construction companies must ensure their systems are secure from data breaches and cyber threats. Robust encryption, user authentication, and regular security audits are now essential components of telematics infrastructure.

Leading Players Investing in Telematics

Several industry giants have made substantial investments in telematics, recognizing its value in optimizing heavy equipment operations:

- Caterpillar Inc. and Komatsu Ltd. have integrated advanced telematics across their equipment lines.

- Trimble Inc. provides end-to-end telematics solutions, including fleet and machine health monitoring.

- Hitachi Construction Machinery and John Deere also offer a wide range of telematics tools, from real-time tracking to productivity analytics.

Final Thoughts

The adoption of telematics in the construction and heavy equipment industry is more than a trend — it's a transformation. With benefits ranging from cost savings and efficiency gains to improved safety and compliance, telematics is shaping the future of construction. As technology continues to advance, companies that embrace telematics today will be better positioned to lead tomorrow’s smart construction revolution.

Contact Us:

UnivDatos

Contact Number - +1 978 733 0253

Email - contact@univdatos.com

Website - https://univdatos.com

Linkedin- https://www.linkedin.com/company/univ-datos-market-insight/mycompany