Introduction

The film forming starches market recent developments highlight rapid advancements in technology, strategic collaborations, application expansions, and regulatory shifts that are reshaping the future for starch‑based biodegradable films. As industries seek sustainable alternatives to conventional plastics, film forming starches—derived from corn, potato, cassava, rice, and other starch‑rich crops—are gaining prominence. Recent developments in formulation science, manufacturing processes, end‑use adoption, and industry partnerships are accelerating commercial adoption and enhancing competitiveness.

Technological Breakthroughs Improving Material Performance

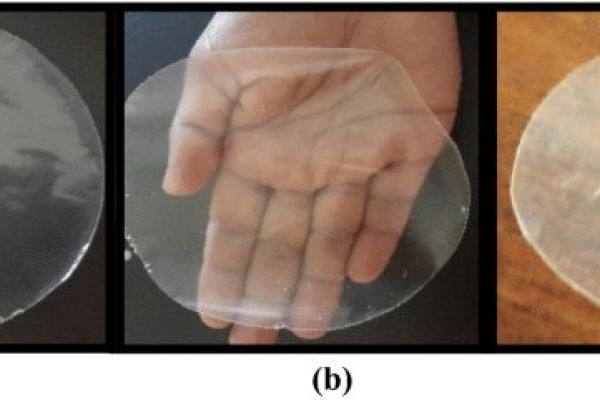

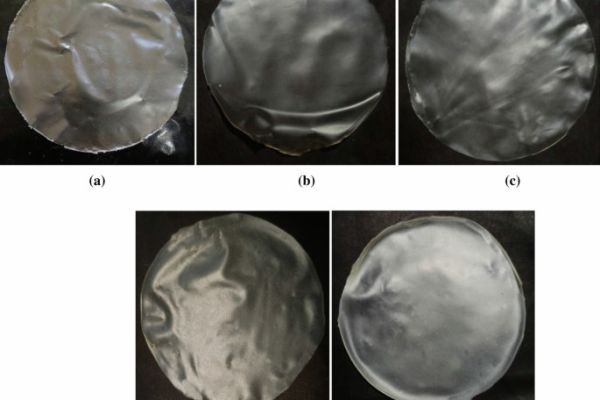

One of the most notable recent developments in the film forming starches market is the significant improvement in material performance through advanced formulations. Traditional starch films often suffered from brittleness, low tensile strength, and poor moisture barrier properties. However, recent research focuses on modified starches created via physical, enzymatic, and bio‑based chemical techniques. These modifications enhance mechanical properties without compromising biodegradability.

Hybrid formulations that combine starch with other biodegradable polymers, such as polylactic acid (PLA), cellulose derivatives, and natural plasticizers, have improved flexibility, strength, and barrier properties. These advancements are enabling starch films to enter applications previously dominated by synthetic plastics, especially in packaging and industrial use.

Development of Functional and Active Films

Emerging applications for film forming starches now include functional and active films designed for enhanced utility. Active films incorporate natural antimicrobial agents, antioxidants, and moisture regulators to improve product shelf life in packaging applications. For instance, certain starch films now include essential oil extracts that inhibit microbial growth in food packaging, offering not just structural support but also functional preservation.

Intelligent films capable of signaling product freshness or environmental conditions are also under development. These smart starch films, embedded with responsive markers or indicators, provide real‑time feedback on food quality, helping reduce waste and improve consumer safety.

Scaling and Process Optimization

Manufacturing scalability has seen notable progress. Recent developments in extrusion, cast film production, and roll‑to‑roll processing have helped reduce costs and improve quality consistency. Advanced process control systems and automation are also enabling high‑volume production of starch‑based films with tighter tolerances and reduced waste.

Enhanced compatibility with existing industrial equipment is another key development. Starch film formulations are being optimized to require minimal changes to conventional plastic film production lines, reducing capital investment barriers and enabling broader industry adoption.

Strategic Industry Partnerships

Collaborative developments have accelerated market growth. Partnerships between starch producers, packaging firms, food manufacturers, and academic institutions are fostering innovation and commercialization. Joint research initiatives focus on refining starch film properties and validating performance in real‑world applications.

Such collaborations share technical knowledge, reduce time to market, and de‑risk development costs. They also create opportunities for co‑branded products and pilot programs that demonstrate viability to larger industrial buyers.

Regulatory and Policy Advances Supporting Adoption

Regulatory developments at national and regional levels are a strong tailwind for the film forming starches market. Governments and environmental agencies in Europe, North America, and parts of Asia are enacting policies to reduce single‑use plastics and incentivize biodegradable materials. These policy shifts encourage companies to integrate starch films into their product portfolios, create compliance pathways, and qualify for sustainability certifications.

In some jurisdictions, subsidies or tax incentives are offered for adopting compostable or bio‑based materials, further supporting market penetration.

Expansion into New End‑Use Markets

Recent developments have broadened the range of end‑use applications for starch films beyond traditional packaging. In agriculture, biodegradable mulch films and seed coatings made from starch are reducing environmental impact while supporting crop health. Controlled‑release nutrient systems using starch matrices are enhancing fertilizer efficiency and soil sustainability.

In the personal care sector, starch films are being tested in single‑use products, like compostable mask sheets and biodegradable wipes. Their non‑toxic, skin‑friendly characteristics make them viable for sensitive applications, expanding market demand beyond industrial segments.

Growth in Pharmaceutical Applications

Pharmaceutical applications have also evolved. Starch films are increasingly used for capsule coatings, dissolvable strips, and blister pack liners due to their biocompatibility and safety profiles. Recent developments include precision‑engineered starch films with controlled disintegration rates, enabling more reliable drug delivery systems. These advances support broader pharmaceutical adoption and position starch films as functional alternatives to synthetic excipients.

Standardization and Certification Progress

Standardization efforts and certification schemes for biodegradable and compostable materials have matured, creating clearer compliance benchmarks. Certifications from recognized bodies help build buyer confidence and validate environmental claims.

Film forming starches that meet international compostability standards can qualify for eco‑labels, enhancing market appeal, particularly in consumer goods and packaging sectors where sustainability messaging influences purchasing decisions.

Consumer Awareness and Brand Adoption

Consumer education campaigns and growing environmental consciousness have shifted preferences toward sustainable packaging. Brands adopting starch‑based films are increasingly highlighting their biodegradability on labels and marketing materials, reinforcing demand and competitive differentiation.

This trend is particularly strong among younger consumers who prioritize environmentally responsible products. Consumer acceptance directly influences corporate procurement decisions and accelerates adoption across industries.

Supply Chain Resilience Initiatives

Recent disruptions in global supply chains have prompted companies to strengthen local sourcing and diversify raw material procurement. For starch film producers, securing reliable agricultural feedstocks while optimizing logistics has become a priority. Investments in regional production facilities and partnerships with local farmers improve supply resilience and cost predictability.

Future Outlook

The cumulative impact of these recent developments suggests a robust trajectory for the film forming starches market. As technology continues to improve, regulatory landscapes evolve, and sustainability imperatives intensify, starch films are poised to expand their role in mainstream markets. Continued innovation—particularly around functional films, performance enhancement, and cost competitiveness—will be critical to unlocking broader adoption.

Conclusion

The film forming starches market has experienced transformative developments across technology, partnerships, regulation, and application expansion. These advances are reducing barriers, enhancing performance, and creating new opportunities in packaging, agriculture, food, pharmaceuticals, and personal care. As industry players continue to innovate and collaborate, the market is well positioned for sustained growth and deeper integration into sustainable supply chains worldwide.