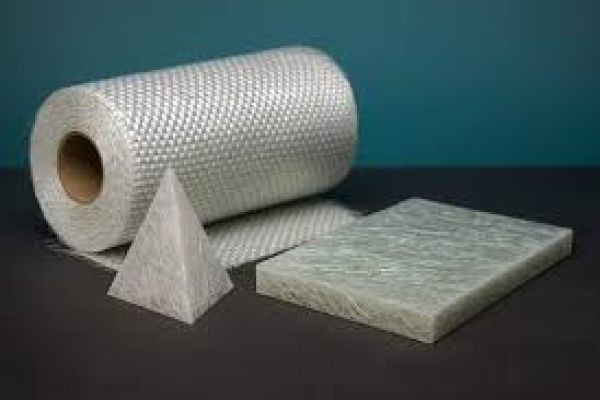

The Glass Fibre Reinforced Plastic (GFRP) Composites Market is witnessing accelerated expansion as industries increasingly adopt lightweight materials to enhance energy efficiency and performance. As manufacturing sectors aim to reduce emissions, extend durability, and improve structural design flexibility, GFRP composites have emerged as a leading solution. With their superior strength-to-weight ratio, corrosion resistance, and cost-effectiveness, these composites are transforming how automotive, aerospace, and construction industries approach material selection and design innovation, fueling global growth projections over the coming decade.

Rising Importance of Lightweight Design

Lightweight design has become a critical focus across industries striving for greater efficiency and sustainability. Reducing material weight without compromising structural integrity allows manufacturers to improve energy savings and minimize operational costs. GFRP composites, being significantly lighter than metals such as steel or aluminum, offer a compelling advantage in this transformation.

The growing need to meet regulatory emissions standards, particularly in transportation and energy sectors, has amplified the adoption of lightweight materials. The ability of GFRP to combine high mechanical strength with reduced mass positions it as a preferred material for next-generation engineering applications.

Growth in the Automotive Sector

The automotive industry remains one of the largest contributors to GFRP demand. Manufacturers are using these composites to replace traditional materials in body panels, chassis components, and interior structures. Lightweight design directly correlates with improved fuel efficiency, enabling vehicles to meet stringent environmental standards while maintaining performance and safety.

Electric vehicle manufacturers are also embracing GFRP components to extend battery life and improve range. As global production of electric and hybrid vehicles expands, the use of glass fiber composites is expected to rise sharply. Continuous research into recyclable composite materials is further enhancing their appeal to automakers aiming for sustainable production processes.

Expanding Role in Aerospace and Defense

Aerospace and defense applications represent another major growth avenue for GFRP composites. Aircraft manufacturers are focusing on weight reduction to optimize fuel consumption and reduce emissions. GFRP materials offer excellent fatigue resistance and dimensional stability, ensuring long-term performance in demanding flight conditions.

Defense sectors are also integrating these composites into military vehicles, protective equipment, and infrastructure projects due to their durability and corrosion resistance. The combination of lightweight construction and high strength-to-weight ratio delivers superior mobility and reliability, key attributes in mission-critical environments.

Infrastructure and Construction Growth

The infrastructure sector is increasingly investing in GFRP for bridge reinforcement, pipelines, and architectural components. Lightweight design supports ease of transportation and installation, reducing project timelines and costs. In regions with challenging climates, GFRP’s resistance to corrosion and chemical degradation enhances structural longevity.

Urbanization trends across Asia-Pacific, Africa, and the Middle East are driving large-scale infrastructure projects, further supporting market expansion. Governments are recognizing the value of composites in creating resilient, sustainable, and cost-efficient construction systems. This has led to new opportunities for manufacturers to supply high-performance GFRP materials for modern city developments and smart infrastructure projects.

Renewable Energy and Marine Applications

In renewable energy, lightweight GFRP composites play an essential role in the production of wind turbine blades and tidal energy systems. Their ability to withstand cyclic stresses and environmental exposure ensures long-term operational reliability. As global investment in renewable energy intensifies, the demand for high-strength, lightweight materials continues to climb.

Marine industries are also benefiting from GFRP’s performance characteristics. Boats, offshore structures, and marine equipment increasingly utilize these composites for corrosion resistance and design flexibility, extending operational lifespan while reducing maintenance requirements.

Regional Growth Projections

Regional analysis indicates that Asia-Pacific will remain the fastest-growing market due to rapid industrialization, government infrastructure investments, and strong manufacturing capacity. China and India are leading the adoption of lightweight composite technologies for both construction and automotive industries.

Europe continues to drive sustainability-focused growth through innovation in recyclable and bio-based GFRP materials. North America’s focus on advanced manufacturing and renewable energy integration further strengthens its market outlook. Emerging economies in Latin America and the Middle East are adopting GFRP solutions for lightweight design in transportation and energy infrastructure, widening the global adoption footprint.

Innovation and Future Trends

Future growth in the GFRP composites market will be defined by advancements in resin systems, process automation, and recycling technologies. Automation will enhance precision and scalability, while new polymer blends will improve heat resistance and mechanical performance. Research into sustainable raw materials will further align GFRP production with global environmental goals.

Manufacturers are also exploring hybrid material designs that combine GFRP with carbon fibers, offering optimized strength and reduced costs. These innovations are expected to strengthen the role of composites in sectors where performance and weight efficiency are critical.

Conclusion

Global demand for lightweight design is set to remain a primary growth catalyst for the GFRP composites market. As industries transition toward sustainability, the material’s balance of strength, cost efficiency, and environmental compatibility ensures its continued relevance. Through ongoing innovation and supportive policy initiatives, GFRP composites will play an increasingly vital role in reshaping the future of mobility, infrastructure, and energy solutions worldwide.