Optic fiber welding, also known as fiber fusion splicing, is the process of joining two optical fibers end-to-end to create a continuous optical path. Unlike traditional cable connections, this process requires extreme precision and cleanliness, as even a microscopic gap can result in signal loss or reflection. In today’s digital age, where data centers, telecommunications, and smart technologies rely on flawless connectivity, optic fiber welding stands as the silent backbone of modern infrastructure.

Understanding the Process of Optic Fiber Welding

The process begins by preparing the optical fibers. Each fiber is stripped of its protective coating to expose the bare glass core. These exposed ends must be carefully cleaned to remove dust or oil that could interfere with light transmission. Once prepared, the fibers are precisely aligned using an advanced splicing machine. This alignment ensures that the fiber cores meet perfectly, allowing the optical signal to pass through without interruption.

A small electric arc, controlled by the splicing device, is then used to heat and fuse the fibers together. This is the welding step—where glass meets glass, forming a single, continuous light path. The weld must be smooth, stable, and free from air bubbles or impurities. After the fusion is complete, a protective sleeve is applied over the joint to provide mechanical strength and shield the splice from environmental damage.

Each step in optic fiber welding is essential. Even a slight deviation in alignment or temperature can affect the signal quality. Therefore, skilled technicians rely on precise equipment and standardized procedures to achieve consistent, reliable welds.

The Role of Optic Fiber Welding in Communication Networks

In communication networks, optic fiber welding ensures uninterrupted transmission of voice, data, and video signals. It plays a major role in connecting fiber optic cables across cities, data centers, and even undersea communication systems. As telecommunication companies upgrade their infrastructure to support 5G and beyond, optic fiber welding becomes more crucial than ever.

Fiber optic connections are not only faster but also more secure than traditional copper cables. However, these fibers are fragile and require careful handling. The welding process ensures that fibers remain intact and perform at maximum efficiency over long distances. In complex networks, hundreds or even thousands of splices may be performed, each demanding precision and reliability.

The same technology extends to industrial automation, aerospace communication systems, and advanced research networks. In each case, optic fiber welding ensures stable data transfer with minimal signal loss.

Equipment Used in Optic Fiber Welding

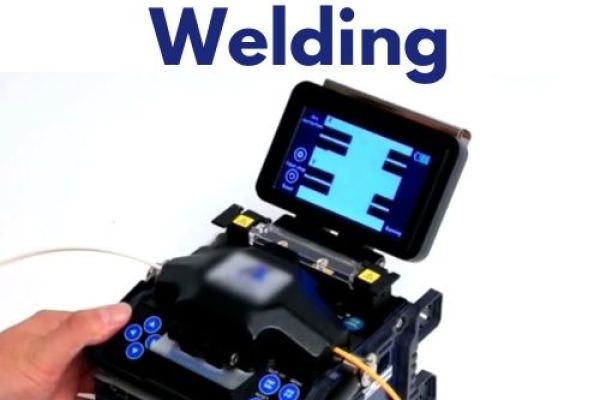

Modern optic fiber welding machines are engineered for accuracy and efficiency. They feature automatic alignment systems that detect and adjust fiber positions with microscopic precision. Built-in cameras and optical sensors analyze the fiber cores and make real-time corrections before the welding arc is applied.

The splicing machine also calculates parameters like arc power, duration, and environmental conditions to ensure optimal welding quality. In addition to the splicer, tools such as cleavers, strippers, and inspection microscopes are used to prepare and test the fibers. The process may seem technical, but it’s designed to deliver long-lasting connections that perform under demanding conditions.

Field technicians often rely on portable fiber welding machines that are lightweight yet powerful enough to handle diverse cable types. These machines simplify field installations and maintenance work, making optic fiber welding practical for both large-scale projects and small network repairs.

Industrial Applications of Optic Fiber Welding

Optic fiber welding has found its place in nearly every sector that depends on high-speed communication. In telecommunications, it forms the backbone of fiber-to-home and fiber-to-building connections. Data centers use welded fiber networks to handle vast amounts of cloud-based data traffic.

In energy and utilities, optic fibers are welded into smart grid networks for real-time monitoring and communication. The oil and gas industry employs fiber optic systems for remote sensing in harsh environments, where welded connections ensure durability and accuracy.

Military and aerospace applications rely on optic fiber welding for secure and interference-free communication links. In healthcare, fiber optic technology supports advanced imaging systems and data transmission for diagnostics. Even in research facilities, optic fiber welding plays a role in connecting experimental setups where precision timing and data integrity are crucial.

The Importance of Quality Control

Every optic fiber weld must undergo inspection and testing to verify its performance. The most common test involves measuring optical loss — the amount of signal attenuation at the welded point. Ideally, a well-performed weld will have minimal loss, often less than 0.02 dB.

Technicians use optical time-domain reflectometers (OTDR) and power meters to evaluate splice quality. These instruments provide detailed readings that help identify weak points or improper connections. Maintaining consistent quality across hundreds of welds ensures that entire networks function efficiently.

Temperature, humidity, and vibration can also affect the welding process. Therefore, technicians often perform splicing in controlled environments or use field enclosures that protect the fibers during installation.

Advancements in Optic Fiber Welding Technology

As global data demand grows, optic fiber welding technology continues to evolve. New generation splicers are now equipped with artificial alignment systems, machine learning calibration, and even environmental compensation features. These improvements minimize human error and speed up the welding process while ensuring exceptional consistency.

Microstructured and specialty fibers — used in sensing and medical applications — have also introduced new welding challenges. To meet these needs, advanced welding systems now offer customizable arc settings and adaptive alignment for fibers with varying geometries or refractive indices.

Automation and robotics have further streamlined large-scale fiber installations. Automated splicing systems can handle multiple fibers simultaneously, reducing downtime and improving throughput. These technological innovations reinforce the importance of optic fiber welding as a foundation of digital transformation.

Maintenance and Longevity of Welded Fiber Connections

Proper maintenance of welded fiber networks ensures long-term stability and performance. Routine inspections help detect early signs of degradation, such as increased signal loss or protective sleeve damage. Regular cleaning of fiber connectors and the use of dust-free enclosures also contribute to preserving signal quality.

Environmental exposure, such as moisture or temperature changes, can impact weld longevity. Protective casings and enclosures are therefore used to safeguard spliced joints, especially in outdoor installations. Over time, monitoring and documentation of weld data allow network engineers to track performance trends and plan proactive maintenance schedules.

Training and Skill Development in Optic Fiber Welding

The success of optic fiber welding depends heavily on the expertise of the technician. Precision handling, equipment calibration, and a deep understanding of fiber behavior are essential. Many institutions and technical programs now offer specialized training in fiber optic welding, combining theoretical knowledge with hands-on experience.

Certified technicians are in high demand across industries, especially as companies continue to expand fiber-based communication systems. This growing demand highlights the critical importance of skill development in sustaining global connectivity infrastructure.

Final Thoughts

Optic fiber welding is far more than a technical process — it is the invisible force enabling our hyper-connected world. Every seamless video call, every data transfer, and every cloud service depends on the integrity of welded optical fibers beneath our feet and across the globe. As innovation continues to advance, optic fiber welding remains central to building faster, smarter, and more reliable communication networks. It ensures that light — the carrier of modern information — flows without interruption, shaping the future of technology and connectivity.