Synthetic Polyisoprene Rubber Market is focusing on reducing production costs while maintaining high elasticity, durability, and chemical resistance. Manufacturers invest in advanced processing techniques, optimized formulations, and sustainable manufacturing practices to deliver reliable and cost-efficient elastomers. Innovations in material design, energy efficiency, and resource utilization support consistent performance. By balancing cost and quality, the market meets stringent industry requirements, enhances competitiveness, and ensures widespread adoption in global applications.

Market Overview

Synthetic polyisoprene rubber is a high-performance elastomer valued for elasticity, mechanical strength, and chemical resistance. Cost-effective solutions aim to optimize raw material usage, reduce energy consumption, and improve manufacturing efficiency. Automotive, healthcare, industrial, and consumer sectors rely on consistent material performance while managing production budgets. Manufacturers explore innovations in polymerization, compounding, and process automation to deliver cost-efficient products without compromising standards. Meeting industry performance requirements ensures market growth and supports adoption across diverse global applications.

Automotive Applications

The automotive sector drives demand for cost-effective synthetic polyisoprene rubber in tires, seals, gaskets, and vibration-damping components. Manufacturers optimize formulations to enhance durability and thermal stability while reducing material costs. Advanced processing techniques, such as energy-efficient mixing and automated production, improve yield and reduce wastage. Electric and hybrid vehicles require tailored solutions that balance performance and cost. Cost-effective innovations help automotive manufacturers meet regulatory standards, maintain vehicle reliability, and ensure widespread adoption of synthetic polyisoprene rubber in critical components.

Healthcare Applications

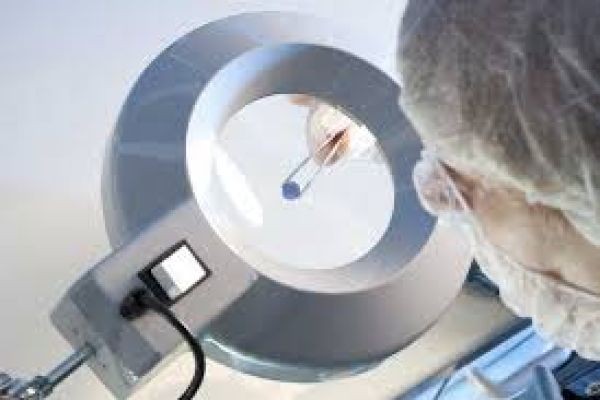

Healthcare products, including medical gloves, tubing, catheters, and surgical instruments, require high-quality elastomers at manageable costs. Manufacturers focus on optimizing production, reducing chemical usage, and improving resource efficiency. Cost-effective solutions maintain biocompatibility, non-allergenic properties, and consistent performance. Research in material formulation and process efficiency ensures reliable supply for hospitals, clinics, and medical device manufacturers. Balancing cost and performance allows synthetic polyisoprene rubber to remain a preferred material in healthcare applications globally.

Industrial Applications

Industrial sectors, including machinery, manufacturing, and construction, use synthetic polyisoprene rubber for hoses, belts, seals, adhesives, and vibration-damping components. Cost-efficient manufacturing supports large-scale adoption while maintaining durability, elasticity, and chemical resistance. Process optimization, automation, and energy-saving technologies reduce production expenses. Industrial demand is driven by infrastructure projects, equipment modernization, and mechanization. Manufacturers providing reliable, cost-effective elastomers enhance competitiveness and meet diverse industrial requirements without compromising performance.

Consumer Products

Consumer goods, including footwear, sports equipment, household items, and elastic materials, increasingly benefit from cost-effective synthetic polyisoprene rubber solutions. Reducing production costs while ensuring product durability and comfort strengthens adoption in urbanizing markets. Manufacturers focus on sustainable practices, energy-efficient production, and optimized formulations to maintain quality at lower expenses. Cost-effective elastomers enable competitive pricing for consumer products while meeting performance expectations, reinforcing market growth in both developed and emerging regions.

Regional Insights

Asia-Pacific leads in adopting cost-effective synthetic polyisoprene rubber solutions due to industrial expansion, automotive growth, and healthcare infrastructure development in China, India, and Southeast Asia. Europe and North America emphasize regulatory compliance, sustainable innovation, and advanced manufacturing techniques to reduce costs. Latin America and the Middle East are emerging markets exploring efficient production methods to maintain competitive pricing. Regional adoption of cost-effective solutions ensures sustainable growth and increased accessibility for diverse applications worldwide.

Market Drivers

Key drivers include the need for affordable high-performance elastomers, rising automotive production, healthcare demand, industrial expansion, and consumer product adoption. Innovations in polymerization, compounding, and process optimization enhance cost efficiency. Sustainable practices and energy-saving technologies reduce production expenses. By addressing cost constraints without compromising material performance, manufacturers meet industry standards, support global supply chains, and promote wider adoption of synthetic polyisoprene rubber.

Challenges

Challenges include raw material price fluctuations, maintaining performance under cost constraints, and competition from alternative elastomers. Manufacturers must optimize production processes, invest in technology, and ensure consistent quality. Balancing cost efficiency with industry performance standards requires careful planning, innovative formulations, and process improvements. Overcoming these challenges is essential for sustaining market growth and delivering reliable, high-quality synthetic polyisoprene rubber at competitive prices.

Future Outlook

The synthetic polyisoprene rubber market is expected to grow as cost-effective solutions enable wider adoption across automotive, healthcare, industrial, and consumer sectors. Advanced processing, optimized formulations, and sustainable practices will strengthen production efficiency and reduce expenses. Regional developments, technological innovations, and increasing industry demand support long-term market expansion. By balancing cost and performance, synthetic polyisoprene rubber will remain a preferred material in global applications, driving both accessibility and innovation.

Conclusion

The synthetic polyisoprene rubber market is actively exploring cost-effective solutions to meet stringent industry performance standards. Automotive, healthcare, industrial, and consumer sectors benefit from optimized formulations, advanced processing, and sustainable manufacturing practices. Cost-efficient strategies reduce production expenses while maintaining elasticity, durability, and chemical resistance. Manufacturers balancing cost and quality enhance competitiveness and support global adoption. Ongoing innovations in process efficiency, material design, and energy utilization ensure that synthetic polyisoprene rubber continues to meet performance requirements worldwide.